INDUCTION FURNACE

- HOME

- INDUCTION FURNACE

Introduce our up-dated induction heating applications such as special brazing of hard and/or diamond tool mostly custom-made under ono-oxidized atmosphere.

Both vertical/horizontal brazing jig in the crystal chamber is now available however conventional.

Induction heating application sample

Induction heating is popular method in the various field of metal base material processing. Introduce most suitable system for various application composed of optimum RF generator, Matching and induction coils.

- ◇Hardening of metal parts

◇Tempering of metal parts

◇Billet heater for thermal forging

◇Billet heater for extrusion

◇Pre-heating for cold working

◇Annealing of metal wire - Called heat treatment process

Rapid heating and cooling produce surface hardening

Deformation processing by metal pre-heating

Stress relief of deformed products

- ◇Copper pipe brazing

◇Carbides/diamond tips brazing

◇Carbides bits brazing

◇Diffused junction

◇Shrink fitting of mechanical parts

◇Releasing parts shrink fixed

◇Shrink fitting of collet chucks

◇Brazing of metal and ceramics - Various application of induction brazing is common method

Brazing in atmosphere, gas atmosphere and vacuum

Diffusion of metal molecule at mutual metal surface produce joint

Shrink fitting and releasing is obtained by thermal expansion of metal

- ◇Direct metal melting & casting

◇Indirect metal melting & casting

◇Continuous metal forging

◇Jewel melting & casting - Process under atmosphere, gas atmosphere and vacuum

Direct melting by using ceramic crucible

Indirect melting by using carbon crucible usually

Less than 100kg melting uses RF induction in general

- ◇Thermo-plastic joint

◇Metal parts Insert

◇Drying coated plastic resin

◇Drying glue rubber on metal

- ◇Getter heating for fluorescent lamp, C-CFL, neon lamp

◇Mono-crystal pulling

◇MOCVD

◇Equipment for metal testing,

◇Superheated steam generation

◇etc

Welcome contact with us on RF Induction heating for subjects of application, trial and improve, etc.

Click here.

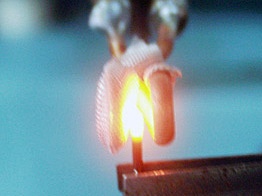

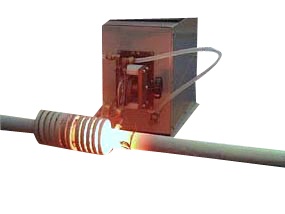

Example of heat treatment of steel: quenching/annealing

Specified area heating is available

Hardening sliding area of internal side of ring

Annealing to prevent crack from welding process

Obtainable hard surface and tough inside of steel material

Rapid heat and cool-down is produced by rotary mechanism

and coolant spray

The higher frequency produce in the thinner area heating

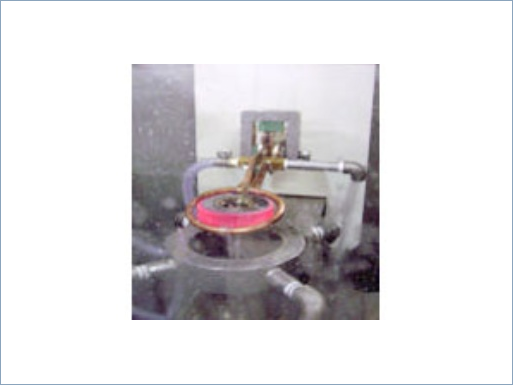

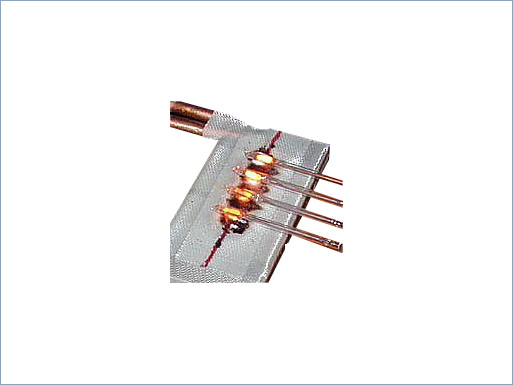

Brazing, soldering, etc

Select most suitable brazing material and flux to match with kinds of material to be jointed

Available non oxidation brazing by combination of RF induction and inert gas atmosphere

Also available for quick and partial soldering process, especially for high-temperature solder such as lead-free

for construction industry

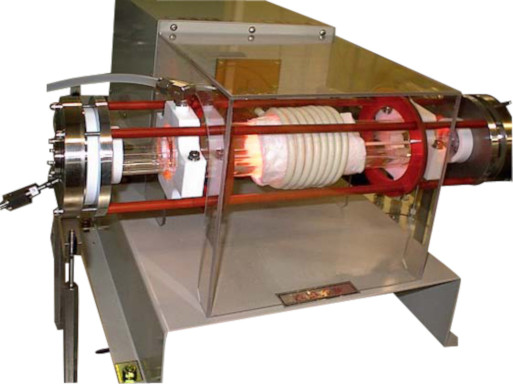

in vacuum chamber

Melting at atmosphere or inert gas atmosphere

Indirect melting

When carbon crucible is heated by RF induction, material charged shall be melted by heat conduction from high temperature of carbon crucible.

Same carbon crucible means no affection to heating efficiency caused by difference of material to be melted

Direct melting

When mainly ceramics crucible is used, conductivity material charged is heated by RF energy directly.

Direct heating of material means free from contamination

Otherwise, heating effect depends upon characteristic of material

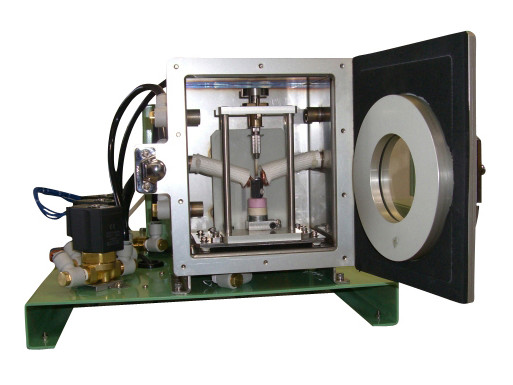

Zone melting

By the electromagnetic field force of heating coil and eddy current flow at material, material will be melted under floating condition at heating coil area

No using of crucible means free from contamination

Shrinkage fitting and releasing

Shrinkage fitting

Thermal expansion of material by RF induction heating is applied for shrink fitting application such as shaft fixing

Application examples are; motor shaft fixing, high speed tool fixing

To obtain expansion of material, external or internal location of heating coil is selectable

Fitting release

In turn, RF induction method is applied for releasing the inserted part by thermal expansion.

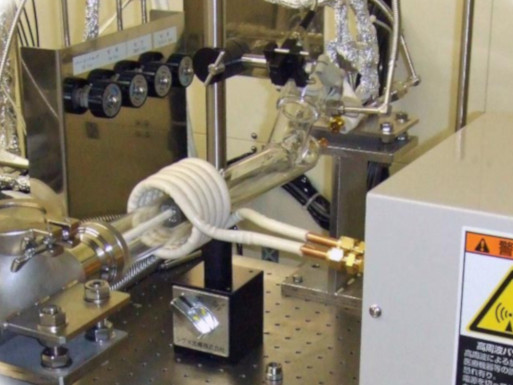

Special application for surface treatment such as thin film formation

The carbon SUSCEPTOR in the quarts chamber is heated up to high temperature by RF induction

When reactant gas is charged into quarts chamber, thin film is formatted on surface of target loaded on SUSCEPTOR.

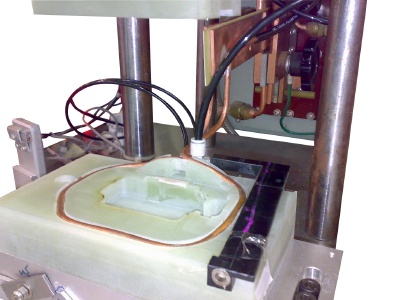

Application for plastic and rubber industries

◇Joint and/or insert in the field of molded plastic parts assembly

◇Joint and/or insert in the field of molded plastic parts assembly

Metal wire or metal net enclosed in the thermo-plastic can easily melt the plastic and obtainable to joint parts or insert metallic fixing.

Example: hermetic sealing by metal wire, knurled nut insertion

◇Drying of coated resin or glue

Heating-up the metallic material quickly by RF induction method, drying process of resin paint or glue coated on surface of metallic material is shortened.

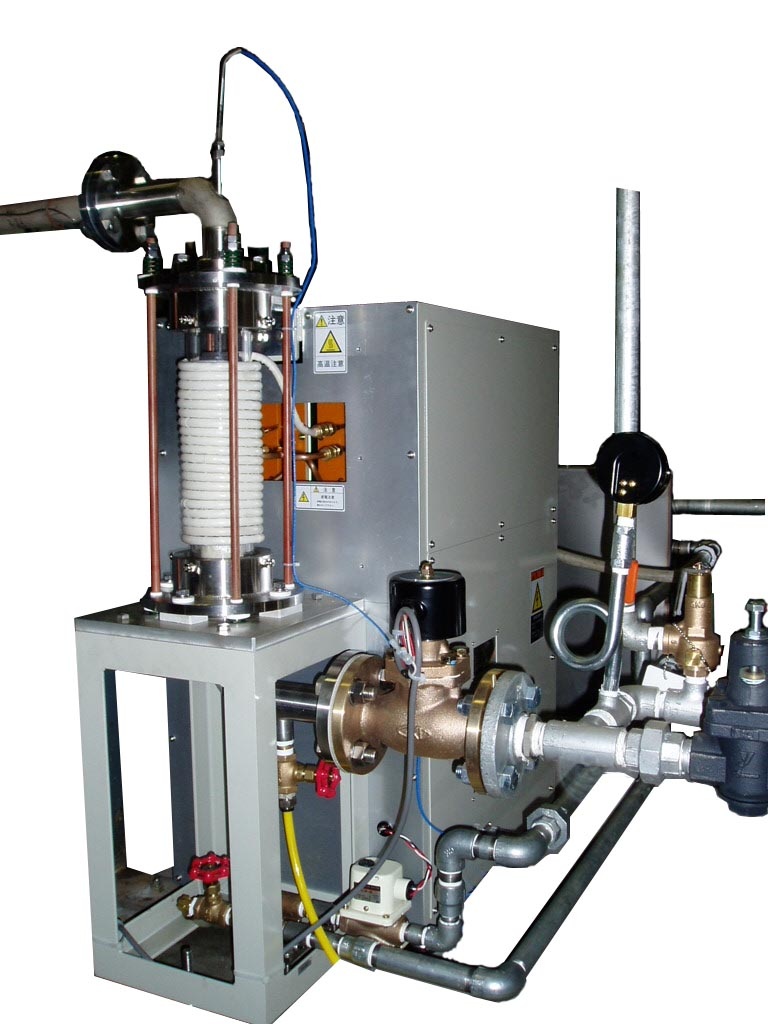

Fluid and/or gas heating

By the method of heat conduction from carbon media to be heated up by RF induction, fluid and gas heating is available.

Carbon media such as lotus root form located inside of quarts chamber is easily heated up by RF induction.

Superheated steam (300 to 800 Celsius) generated has high enthalpy and applied for unique application.

Liquid body such as pure water heat-up is obtainable by using GLC(Glass Like Carbon) media without contamination

For small diameter wire heating and/or thin film of metallic material heating

400kHz to 1.5 MHz utilization

Particular application example

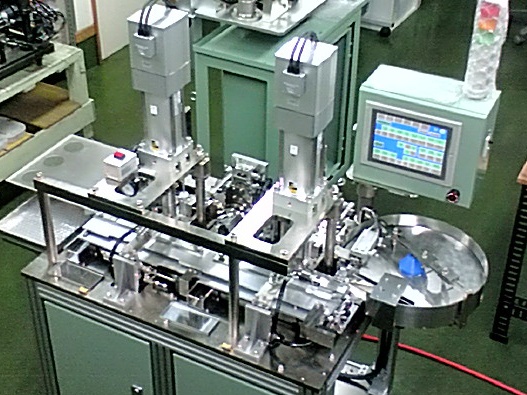

RF induction heating technology, utilization of sensor and robot and human interface

Fully automated system for precise parts production process is realized based on above technical elements organization.

Co-operation with maker and user starting from fundamental test and designing has led its successful result