HF(RF)PRE-HEATERS

- HOME

- HF(RF)PRE-HEATERS

Standard manual HF Pre-heaters (SPECIFICATION TABLE)

I.mecs has been beside of our users for more than 40 years and continued to develop better method, improved machine and customer satisfaction

I.mecs has been beside of our users for more than 40 years and continued to develop better method, improved machine and customer satisfaction

★ Safety operation ----------- Eliminate mechnical & electrical danger

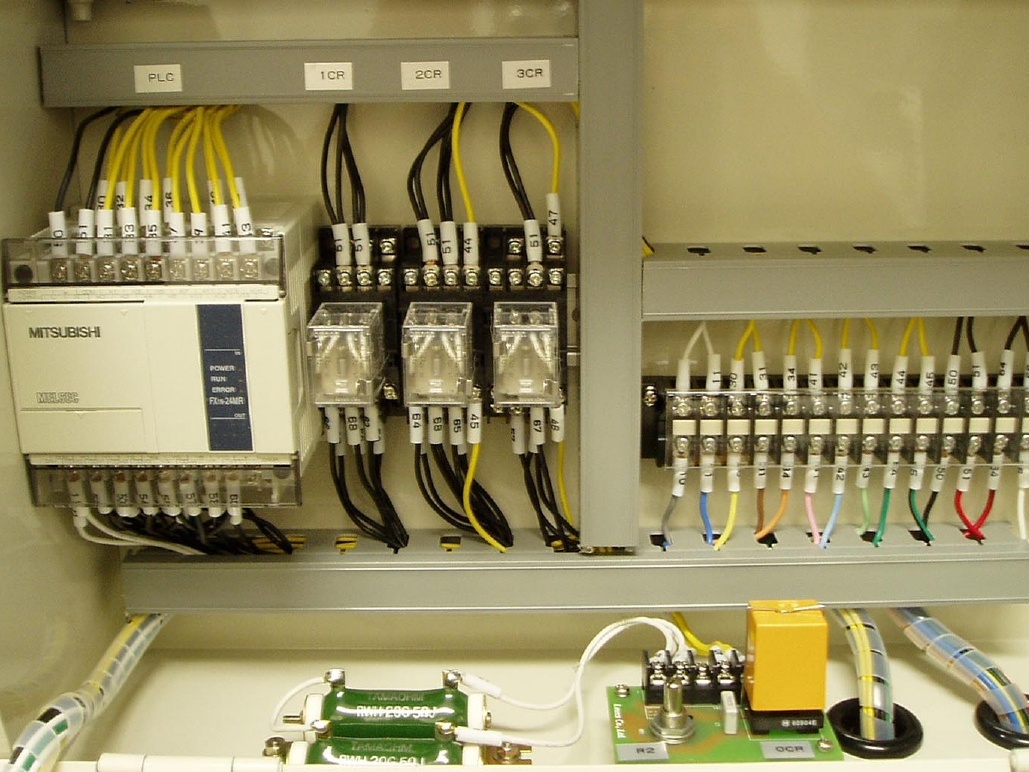

★ Stable operation ----------- PLC of control circuit and solid-type sensors

★ Easy operation ------------ Visible heated result and observation of oscillation condition

★ Minimize parts consumption-- Mechanical & elecrical counter-plan

Based on above concepts, we offer various solutions to meet with customers requirements

/special pellets guide

Additional electrode for temp. distribution

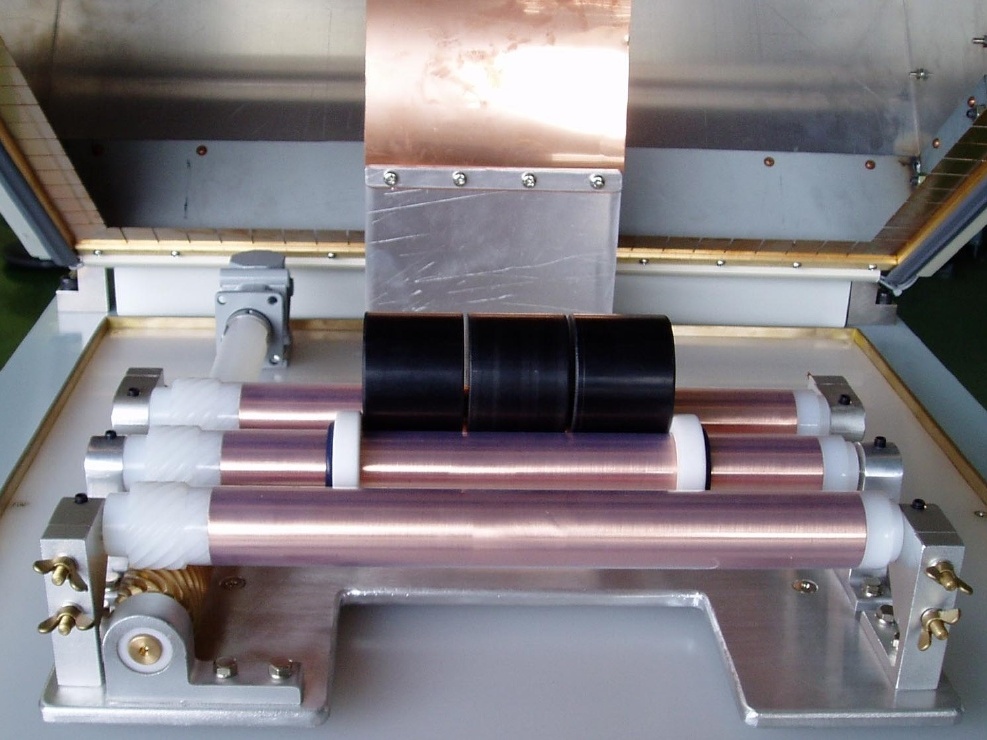

HF Pre-heater uses mainly an electron tube and forced air-cooling system.

Therefore dust from the outside of the equipment causes the largest troubles.

I.mecs new standard type IMC-PH-V3 series are changed the structure of air-inlet and adopted the polyester dust-filter.

IMC-3F-V4(3kw)/IMC-5F-V4(5kw)

・ IMC-PH-V3 series are special HF Pre-heater to make the food samples.

・ Heat zone is 150mm high, so this is able to heat a large cooking sample.

・ Adjustment of the heat zone is voluntarily available by push button and it becomes so easy to use.

Indispensable equipment to produce the food sampe

Details about the thermal curing step of vinyl chloride sol and the use of HF Pre-heater

□ HF Pre-heater can heat rapidly and uniformly the internal and external parts of sol.

□ HF Pre-heater can not heat silicon type ingredients, so they are heated by the microwave oven.

□ HF pre-heater is capable of using suitable for the thick or thin ingredients.

Feature of HF Pre-heater

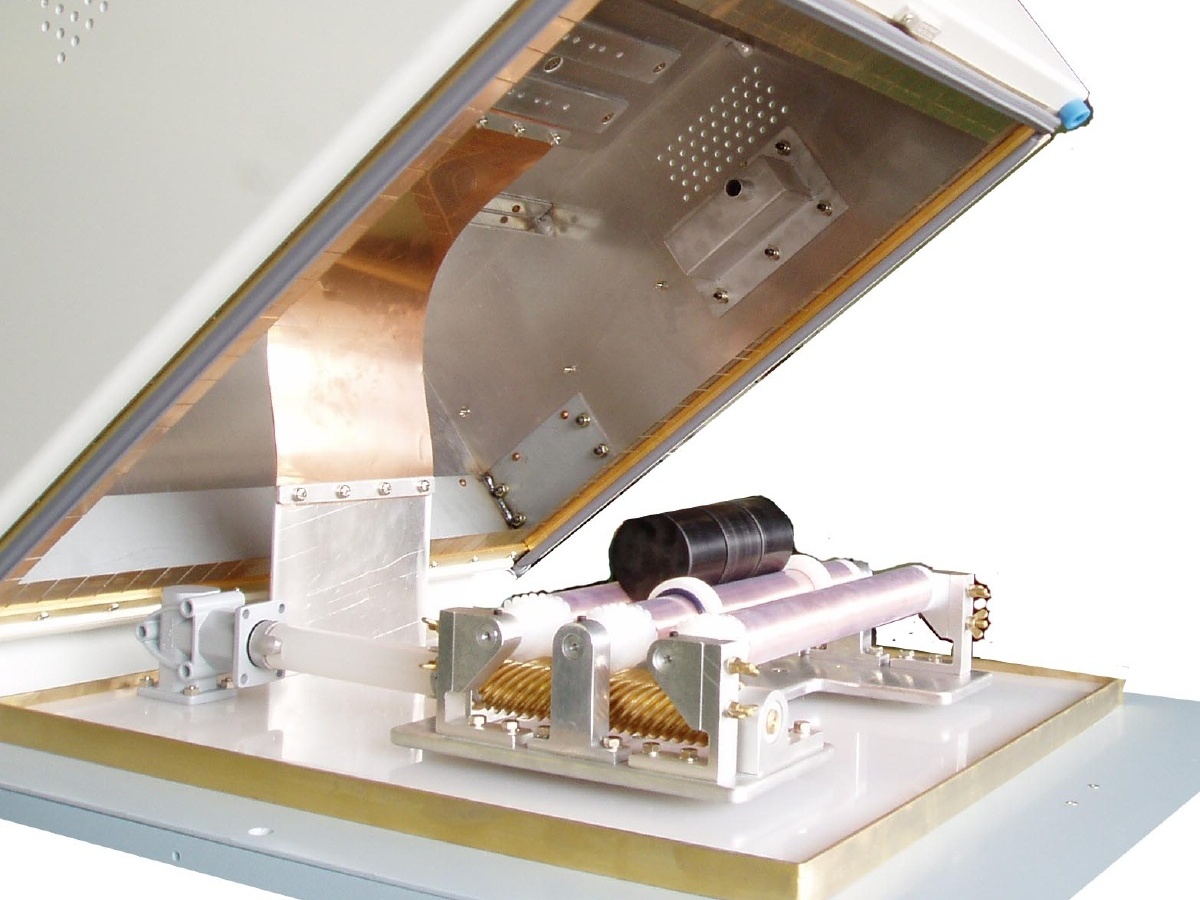

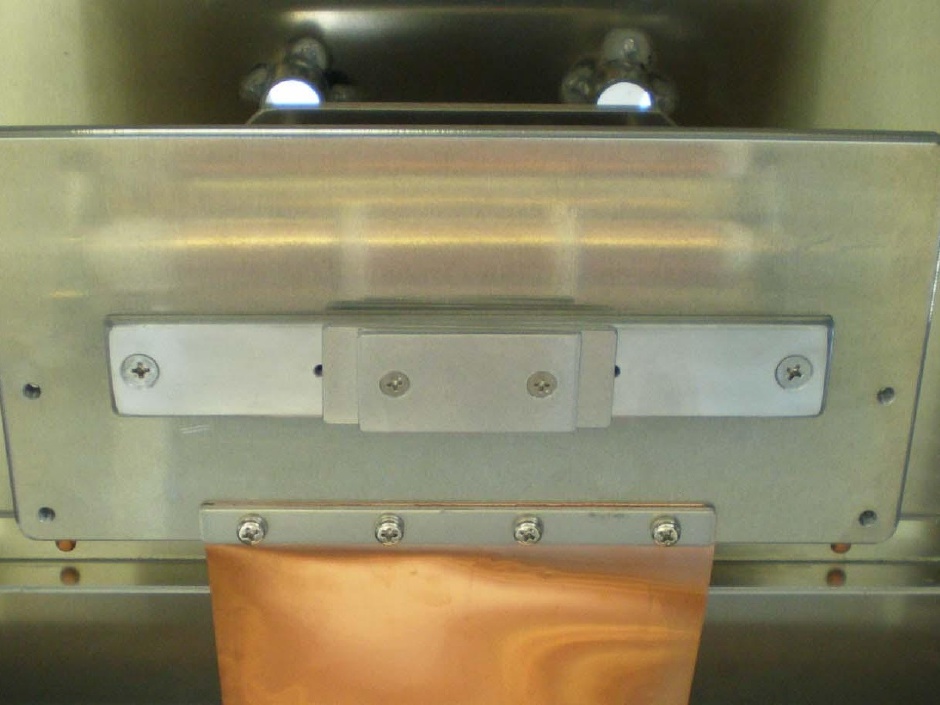

The space between upper electrode and lower electrode is wide,

so it can make the thick products and high products.

Conventional equipment : The space is 30mm ~80mm.

New equipment : The space is 50mm ~180mm.

There are some new equipments which are possible to heat to vertical direction or horizon direction.

By an electrode elevating mechanism, it is possible to set the space of electrodes in the operation of the push button

With the door opened, the electrode elevatingis possible,

so visual viewing of the optimum state is also made possible.

HF Pre-heater only for the food sample

3kw HF output power

The food samples such as confectionary and cooking are produced by world-class Japanese technology.

I.mecs has developed and provided the HF Pre-heater only for the food samples production.

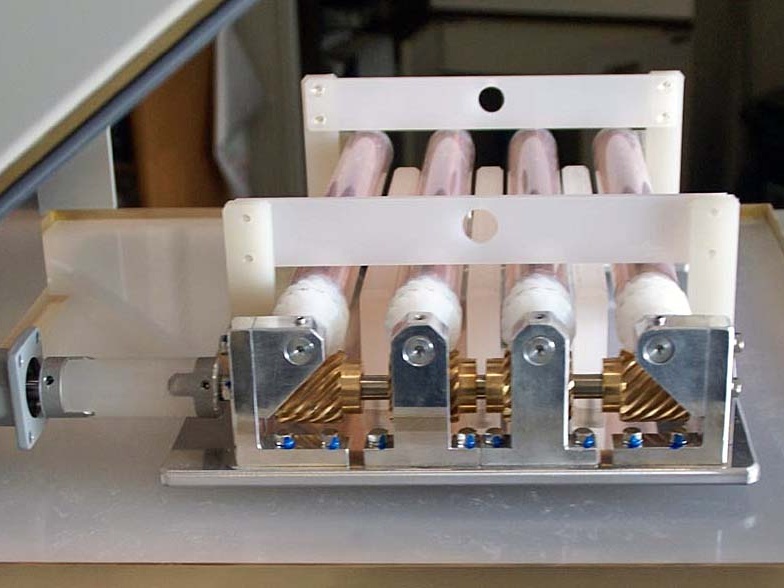

Automated HF Pre-heaters

For fully automated molding process;

1. We provide HF Pre-heaters built-in Pellets(Tablets) handling system

2. Pellets (Tablets) handling system load it on to electrode of pre-heater and in to pot of mold die.

3. Fully automated mold system will be presented to not only electronic devise but mechanical parts manufacturer.

Following photos show our typical HF Pre-heaters combined pellets handling system

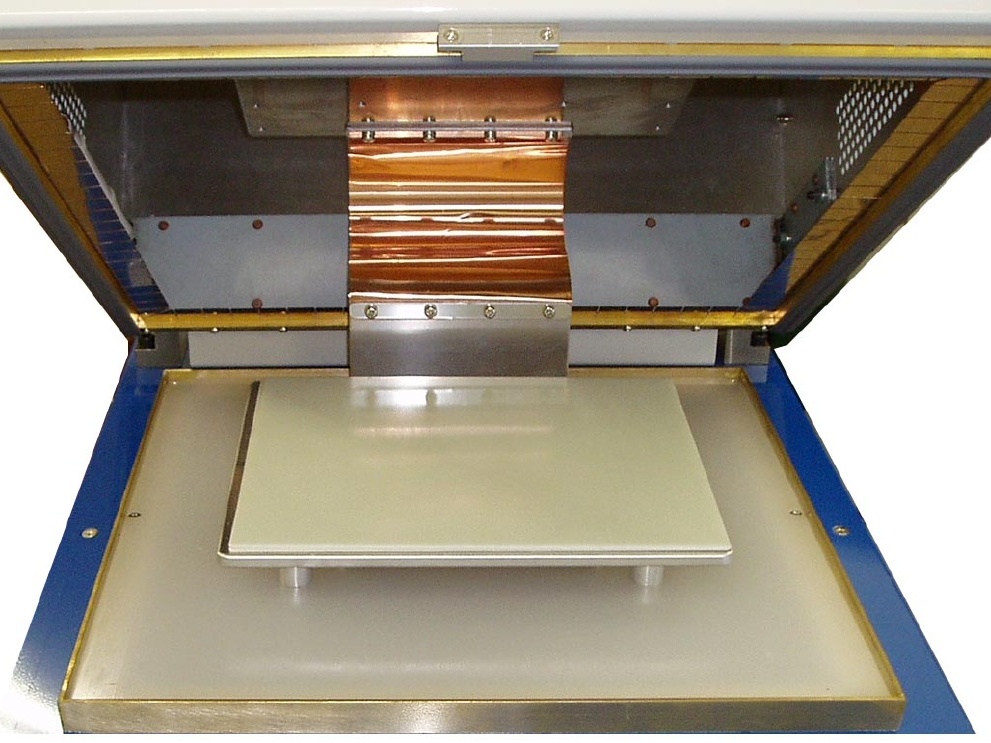

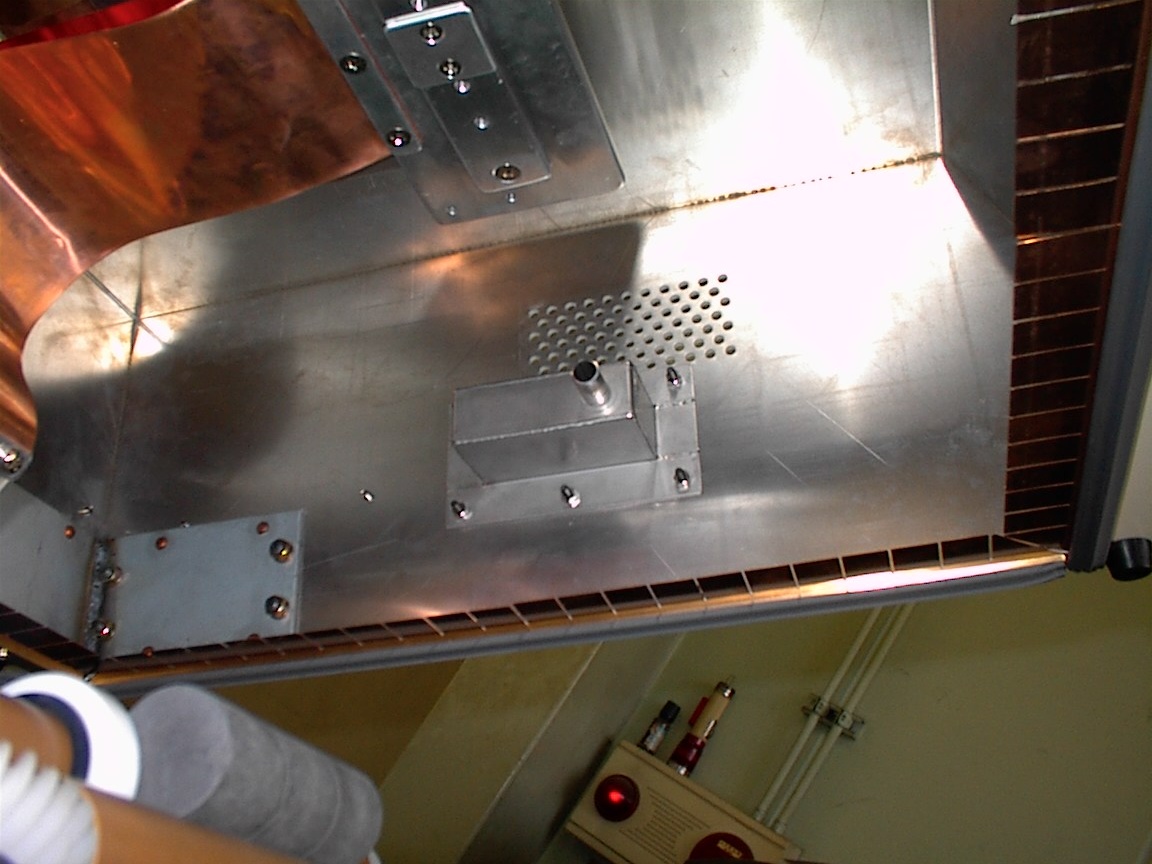

Specila purpose HF Pre-heaters

manufacturing and capable to load large size material

Liquid PVC sol is cured by Radio Frequency Energy quickly

Regular maintenance, overhaul, repairing and improving

For safety and stable operation, we recommend REGULAR MAINTENANCE service

・Available for both our brand and other brand

・Contact with us for more nformation in detail

Available to be at your site when in emergency

・Call or contact with us when facing trouble or damage

・Before contact with us, fill out "TROUBLE INFORMATION SHHET"

・After communication, visiting site will be decided

Also contact with us when concern following items

・Improve temperature distribution

・Minimize instant operation trouble

・Enforce operator's safety

Based on the principl of dielectric heating;

Based on the principl of dielectric heating;

(1) Temperature heated vary on initial temp, moisture content, pelletsdensity, etc

(2) Temperatur heated vary on loaded position of pellets

(3) Heating time vay on the distance of Top & Bottom electorde

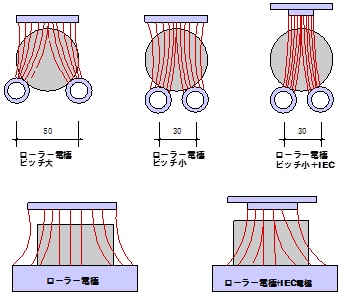

(4) Temperature distribution vary on the pitch of roller electrode

Providing spare parts

Available to provide not only electrical but mehnaical parts even if other brand if possible.

Contact with us when you have following;

Name of parts un-known

Location of parts un-known

---- We will provide parts location photos if required

(Oscillation/Vacuum tube)